Volunteers for the week were Taka Sakai, Frank Kunsaitis, Doug Newberry, Carl Pickus, Richard Berk, and John Salvini.

SP3100

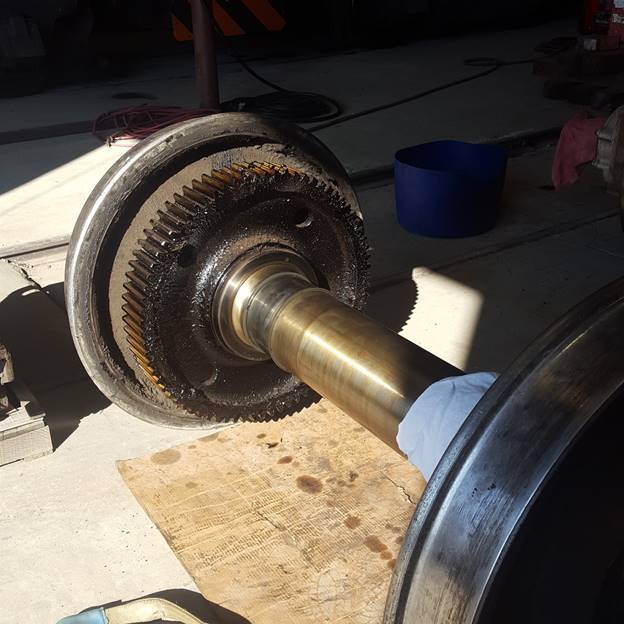

During the week, John, Richard, Carl, and Doug, continued working on replacing the #2 wheel set. Last week they had placed the combo on its tail and removed the gear-case. This week they removed the support bearing caps, axle shield, and the wheel set itself. Then they began the process of cleaning the parts to get ready for installing the replacement axle. They spent many hours cleaning old grease and dirt off the traction motor and gear cases. John tackled the task of removing most of the crater grease from the gear case covers. That must be one of the messiest jobs to deal with while working on locomotives. This picture shows what it still looks like after the residual grease has been scraped out. Of course, there is no reason to get it any cleaner because new grease will be put right back in after the gear cases are reattached to the traction motor wheel set.

The wheel set that was removed had very good-looking axle journal surfaces and the support bearings also looked in fine shape. The bull gear on the axle and the pinion gear on the traction motor showed no sign of wear.

Richard has ordered all the gaskets and seals required to reassemble the replacement wheel set onto the traction motor. Those parts should arrive later this week.

Richard is also trying to solve the mystery of why the oil cooler, that was sent out for refurbishment, has different size gaskets than what are shown in the parts books. It seems that a special request may need to be issued to the company that makes the gaskets so that they will cut a unique sized gasket that will fit our oil cooler. The U25 was a short-lived GE design, so many of the parts books just don’t apply. Until those special gaskets are obtained, the refurbishment of the oil cooler is on-hold. The oil cooler has already been refurbished but can’t be reassembled until those gaskets are obtained.

SP1006

When SP1006 was put into service after its refurbishment, there were reports that the brakes on the locomotive weren’t releasing quickly. That resulted in poor handling qualities. Ryan Keck looked over the air brake system and verified the problem. He found residual rust in the distributing valve and a plugged quick release valve on the rear truck. He replaced the distributing valve with a rebuilt unit and removed the plug from the bottom of the quick release valve. That solved the problem.

During the refurbishment project, a different type quick release valve was added to the main brake pipe because the SW1 was never equipped with one. Those valves become important when applying brakes on a long train. They help vent brake pipe pressure when an automatic application is taken. However, those quick release valves, that we were familiar with, have nothing to do with the brakes on the locomotive.

Saturday, Ryan pointed out two other quick release valves that are part of the locomotive brakes. We, as the restoration crew, were not aware that those devices were quick release valves. We thought they were dirt collectors so didn’t pay much attention to them. We never noticed that one of them had its output port plugged. After Ryan removed the plug, the brakes worked fine. We ran the locomotive back and forth to the Book Store a couple of times and everything seems to be working correctly now.

We now know that these things are quick release valves, not dirt collectors. This picture shows the quick release valve as it feeds into the truck cut-out cock.

OERM 1956

Last week it was discovered that the front headlight had a severely damage light socket. Taka was able to find a correct replacement socket. He rebuilt the complete holder fixture. As always, when Taka works on something, it ends up being a work of art. This shows the rebuilt unit. He then reinstalled it on the locomotive and it worked great.

OERM 1956 and OERM 1975

We have three ALCo locomotives that use the same model Diesel engine. It is a McIntosh & Seymor Model 539 rated at 1000 Hp. It is a six-cylinder engine that was designed in the late 1930’s and was very successful in its day. Of our three locomotives with this model engine, only one runs as it should, with no issues or smoke out the exhaust stack. That one is our ALCo S4 locomotive, SP1474.

The other two, 1956 and 1975, have had issues since they arrived at the museum. During warm weather they start easily, and the exhaust is clear. But in cold weather they still start OK, but the exhaust will put out clouds of smoke. Fortunately, these engines have levers for disabling specific cylinders if needed. We know from experience that when the engines do smoke on start-up that there are only certain cylinders that are misfiring. A quick test with the cutout levers can identify the misfiring cylinders. Once they are disabled, and the exhaust will be totally clear.

OERM 1975 has had this problem for many years and 1956 has been less susceptible to it. But when its cold outside, both have the problem. Saturday cylinders 1,5,&6 had to be disabled on 1975 for it to have a clear exhaust. That meant that it was running on just three cylinders. Cylinders 5, &6 had to be disabled on 1956.

Something is obviously wrong, but we don’t know what yet. Taka replaced all the injectors on 1975 last year but it didn’t appear to make much of a difference. Our next effort will be to have a dummy injector body fabricated that will allow a pressure gauge to be installed for measuring compression. There are steel plugs in the side of the heads for taking compression readings. However, they are so tight that we risk twisting them off and won’t use them.

It is highly likely that the compression readings will be low. But we just don’t know yet. And of course, fixing low compression problems usually isn’t an easy thing to. If we are lucky, it may be nothing more than removing heads and refurbishing the valves and valve seats. But if that isn’t the main problem then piston rings and maybe cylinders liners will need to be replaced. That is not an easy job, but it may need to be done. We will know more after taking the compression readings.

Coolant Replacement Project

Locomotive cooling systems consist of numerous parts that are made from different metals and are interconnected using rubber hoses. This design is a perfect scenario for electrolysis to take place which will seriously damage a locomotive Diesel engine and its cooling system. From the early days of Diesel locomotives, and even steam engines, the manufacturers clearly stated that the water used in boilers and cooling systems had to be treated with chemicals to avoid accumulation of mineral deposits and corrosion. However, many locomotive owners didn’t want to invest in the special chemicals and used non-treated plain water instead. The predictable results were that the engines became severely corroded which often lead to failure of pumps, radiators, holding tanks, and even the engine itself if its coolant passages became plugged with rust and deposits.

Unfortunately, most of the locomotives at the museum suffered this fate for many years. We will now try to remedy the situation as best possible.

The easiest approach is to flush out as much of the rust and corrosion as possible and then add fresh water that has been properly treated with anti-corrosion chemicals. We started this project last summer however our supplier of chemicals was unable to supply the chemical in bulk to us. As a result, we switched vendors and now use a liquid chemical rather than a granular one. The mixing ratio for the new liquid chemical adds two oz of chemical for each gallon of water. The water then turns color to look like Hawaiian Punch. It is a deep reddish purple.

We are now in the process of flushing the coolant systems on all our operational locomotives and refilling them with the new mixture. Last week we refilled 1956, 1474, and 7441. This week we refilled 1975 and 1006. In the next few weeks, UP942, USAF 1601, and SF108 will be flushed and refilled. SP3100 will be refilled with the new mixture after the wheel replacement project is complete and the refurbished oil cooler installed.

This shows the refilling of 1975 Saturday.

We are still unsure how long the chemicals will last. Some of the locomotives have severe corrosion inside and our expectation is that those locomotives will need more chemical added regularly until the red color remains constant. We also have a titration kit available which will allow us to measure the actual concentration of the chemicals rather than just depend on the red color intensity for its apparent effectiveness. This will be a learning experience for us. But we know it must be done if we expect the locomotives to continue to operate for many more years.