Diesel Service Report, Section 1, June 13th, 2020

This week’s report will be issued as two separate reports. This initial report will cover the weeks activities on all the locomotives except for SF560, which is our Fairbanks Morse locomotive, and will be covered in the second section of the weekly report. SF560 has reached a milestone in the investigation looking into restoring it and the discussion explaining the progress is too long to include in this section of the report.

USAF 7441

Bob Bray and Tim Johnson worked Saturday removing more of the painted tar like coating substance inside the cab. It appears that the tar substance was sprayed all over the walls and ceiling inside the cab and then painted either Forest Green or a gray color. The actual purpose for the coating is unclear. Most probably it was intended to act as a vibration dampener on the plate steel walls to deaden noise but that is just speculation. Tom Platten continued to research the correct upholstery material for the seats and for the detachable arm rests which fit over the windowsills on both sides of the cab.

This picture shows Bob removing the tar coating from the inside of the front cab door. Much of the material was very loose and fell off in large chunks. In other areas, the material has been almost impossible to get off.

This shows Tim working around the Engineers seat, attempting to remove as much of the tar material as possible. It also clearly shows the painted tar coating on the inside of the cab rear door.

Last week work was done to try and stop the continued runaway that both engines were starting to experience right after start-up. The locomotive has been used of number of times since that work was completed and, as of now, no more runaway conditions have been experienced. As a best guess, the problem was fixed by replacing a double lip shaft seal around each of the fuel pump drive shafts. Others have said that the runaway mode was caused by air being sucked into the fuel stream in the high-pressure pump side when that seal fails. There is no way to prove it other than to witness that the engines no longer go into the runaway condition. So far, it looks promising.

USAF 1601

Locomotive 1601, our 80 ton GE switcher, arrived at the museum a few years ago, with two of its traction motors disconnected. There was one motor on each of the two trucks that was damaged and had been taken out of the circuits. We have searched for several years for replacement traction motors but always found the prices for the GE747 traction motors to be way above what we considered reasonable. Two weeks ago, Phil Palmieri found a complete truck, with two traction motors, two gear cases, two wheel sets, and all the brake rigging, for sale on an internet web site. The price for the complete truck was much less than we could previously purchase just two traction motors for. Negotiations were opened and the truck was purchased thanks to donations from museum members. The locomotive truck was loaded onto a semi-truck flatbed trailer last Wednesday and is expected to arrive at the museum in the next day or so. Carl Pickus has the large crane located by CB7 ready to unload the new truck and set it on track one.

After the truck arrives, 1601 will be jacked up and its two trucks will be rolled out from under it. The locomotive body will then be placed on blocks. The next step will be to count teeth on the intermediate gear in the gear cases to ensure that the gear ratios are the same between the new truck and the existing truck. If they are the same, then the new gear case, with traction motor and wheel set, which is called a “combo”, will be installed in palace of the existing one. If the gear ratios are not the same, then the GE 747 traction motors from the new truck will be installed into 1601’s original trucks. Once all that work is done, the wiring for those two replaced motors will reconnected and all four traction motors will be again operational.

OERM 1975

This locomotive is typically left outside during all sorts of weather. Every year, after the winter rains, a hot box occurs in one specific journal bearing. These are friction type journal bearings that use cotton wicks that sit in an oil sump. The oil wicks up through the cotton which is rubbing against the bottom of the axle. The wicked oil then spreads a very thin film of oil onto the axle and as the axle turns, that oil film is spread between the steel axle and the brass bearing on top of the axle. That microscopically thin film of oil, which is in all the support bearings on the locomotive, supports the weight of the locomotive minus the weight of the trucks.

But during the winter rains, there is a problem with one journal box on 1975. Water somehow finds its way into the journal box. The oil in the journal box floats on the water. As the water level reaches a certain upper level, the oil on top of the water leaks out through the rear seal of the journal box and there is no oil left in the journal box. Water then wicks up through the journal pad and there is little lubrication between the axle and the journal brass bearing. That’s when things get very hot in the journal box.

We have dealt with this so often that the procedure now is well understood. Frank Kunsaitis is our hot box expert. He removes the water from the journal box and refills the box with journal oil. In addition, he pours oil over the top of the journal bearing to get oil back into the upper portion of the wick. He used to change the journal pad when this problem occurred but found that once the water was removed, and oil added, that the oil would push the water out of the original journal pad and the oil would then again be providing good lubrication between the axle and the journal brass.

UP942 and SP3100

On Wednesday and Thursday of this week, UP942 and SP3100 were laser scanned by a model train company. The company will use that laser scanning data to make very accurate models of EMD E8 and GE U25B locomotives. The process takes them well over a year as drawings are made from the digital scans, molds made for plastic injection operations, and models assembled and painted. After the models are assembled, they are painted in various color schemes for the different railroads that operated these models of locomotives. The company asked that we not reveal who they are to keep their competition from knowing that it was done. Sometime in the next year or two, we will most likely see high quality model replicas of both of our locomotives.

Dave Althaus

Diesel Service Report, Section Two, June 13th, 2020

SF560

Summary:

During the past few months, Diesel Service has been evaluating SF560 for possible restoration. That analysis was focused on identifying issues with the locomotive that may preclude it from being considered for restoration to operational status. We have almost completed that investigation and have identified one major issue that must be solved before we continue with the project.

The museum’s stated goal is to “restore and operate” collectable railroad artifacts from railroads associated with the South West United States. The relevant key word in that statement is the word “operate”.

SF560 was operational, with issues, when it arrived at the museum in the early 1990’s. The issues were identified as blowing oil out the exhaust stack and having a hot box on one wheel. Other than those two issues, we operated the locomotive with no other major problems being noted.

Now in our attempt to start the Diesel engine again, after about 25 years of it sitting idle, we have run into an issue. During that period, all the injection pumps have frozen up. The engine will not run until that problem is solved. We do not have the expertise, facilities, or spare parts to overhaul injection parts. They must be sent out to qualified shops that are set up to repair and test the units.

Before we can send the units out for repair, we must know that we have a way to pay for that work. That money should not be taken out of the normal Diesel locomotive repair budget. If it were, it would severely deplete the fund that we need to support the rest of the locomotives for the rest of the year.

So, we need to raise enough money to pay for the injection pump and nozzle repair. A preliminary estimate from one of the better-known injection pump repair companies, that specializes in Fairbanks Morse pump repair, is $500 per pump and nozzle set. There are 12 of those sets in SF560. And that price does not include any parts that need to be replaced. An estimate at this time is that we need to raise upwards of $10,000 before we can send the pumps and injectors out for repair.

After it was announced that we were considering restoring SF560, numerous offers of donations have been made. We now have an approved account set up for accumulating the donations for SF560.

Any donations made for the restoration of SF560 should reference account number “M56”, SF560 Restoration. We need at least $6000 to start with and that could easily increase to $10,000 once the pumps are sent out for repair and the required parts identified.

Additional Required Funding

We recently finished restoring SP1006. It required much more work and a higher cost than will be required for SF560. We spent someplace close to $80,000 restoring SP1006 so we will estimate that the bottom-line cost for restoring SF560 will breakout roughly like this.

- $10,000 Diesel Engine Fuel Pump Repair

- $20,000 Diesel Engine Blower overhaul (maybe)

- $35,000 Painting

- $3,000 New glazing

- $5,000 Unidentified

$73,000 Total

The blower repair for $20,000 cannot be determined yet. Most probably we could operate the engine without that overhaul but if it blows excess oil out the stack, we will be forced to have the blower rebuilt.

What this all summarizes is that we need $10,000 now and up to $63,000 more during the life of the restoration. That may be a little high based on our experiences with UP942, SP1006, SP3100, and SF108, but we expect that these numbers fairly represent what will be required based on our history.

We have had a lot of encouragement to go ahead with this project and as a result, have put the work into identifying what needs to be done and what it will cost. No further work will be done on the locomotive until we are able to fund the fuel pump and nozzle repair work.

Restoration Decision Background

After SP1006 was finished, we in Diesel Service were pretty burned out. We had spent 18 years on an exceedingly difficult restoration project and weren’t in the mood to start another major project like that. But we also know that our satisfaction working as volunteers at the museum extends beyond changing oil and keeping operational locomotives functional. Our unspoken goal is to restore and maintain Diesel locomotives.

SP2958 & SP2954

Since we all pretty well felt that way, our next step was to look at the potential restoration projects. There were only two projects that had any reasonable possibility of being considered. The first consideration was the restoration of one or both of the RSD12’s, SP2954 & SP2958. There is some budget already available for that project, so it was clear that we needed to understand the scope of work before deciding for or against that work.

- Each of the locomotives has severely worn wheel sets. There are six axles on each locomotive. We have spare wheel sets in outside storage and, based on our work on the SP1006 project, we believe we could most probably restore the support bearing journals. The wheel sets were put into outside storage with no protection over the highly polished journal surfaces and could possibly not be usable anymore. This is a very high-risk problem and constitutes a large amount of work on three axle trucks that we have never worked on before.

- The body work required, as part of a refurbishment project, is extensive on both locomotives. We know that most of the body work done on SP1006 was done single handedly by Carl Pickus. Restoring the sheet-metal, couplers, walkways, handrails, doors, windows, radiators, etc, is way beyond anything Carl could do alone and essentially none of us are enthused about even attempting it. It would take multiple years of a lot of hard work for everyone involved.

- One of the two RSD12’s has after market radiators. Replacement radiators are on hand and could be installed.

- The electrical system on the RSD12’s is a very unique Amplidyne system that utilizes saturable reactor (transformer) controls for many functions. When those systems work, they work well. But when they fail, they are very difficult to troubleshoot and require extremely rare spare parts.

In Summary, a near term goal for the two RSD12’s could be to install the replacement radiators, install new batteries sets, repair broken doors that must be fixed, and understand that the severely flattened wheels would be something to just live with. There is also an exceedingly high risk that the injection pumps and injectors are frozen, just as they are on SF560. The conclusions reached by the Diesel Service crew is that restoring the RSD12’s just isn’t something that we are prepared to commit to at this time.

We learned a lot from our SP1006 project and one of the key bits of wisdom was to ensure that we would never again attempt a project that had the very real risk of not being able to be finished.

SF560

The Fairbanks Morse H12-44M locomotive came to OERM in the early 1990’s. Shortly after it arrived, it was started and ran on a temporary basis just to prove that it could run. All systems operated normally. There was one journal bearing that overheated but those are typically repaired quite easily.

There was a slight leak in one of the air brake system lines leading to an underfloor equalizing reference tank. That leak was traced to a leaking seal under the brake stand and was not repaired. Everything else worked on the locomotive. The locomotive was then drained of water and had the batteries removed. It wasn’t touched again until now, about 25 years later.

These are the issues that we see that must be dealt with if we elect to restore SF560.

- The Diesel engine will not start. After the very long out-of-service time, the fuel injection pumps are frozen and must be repaired. We can’t do that work.

- The engine had leaked oil for many years in the engine compartment. It is by far the dirtiest engine compartment we have ever seen. Its even worse than SP1006 was when we started that project.

- The engine spit oil out of the exhaust for so many years that the running boards looked like they had been coated with a thick layer of tar. That has now dried enough that it falls right off the sheet metal. But it brings up the obvious question regarding the engine blower having bad seals. John Salvini found that the air cleaners were totally plugged, which could have been the reason for the blower possibly sucking oil through its seals. We just don’t know and won’t have that answer until after the engine is running and the air cleaners have been cleaned.

- One brake cylinder needs repacking. Most likely all would need to be repacked after being out of service for that long.

- The mechanical radiator fan was removed before we received the locomotive and an electrically driven one was installed but never connected to electrical power. We would need to install a new contactor and run the fan off 75 VDC. We tested the fan with that voltage and it worked great.

- There is essentially no paint left on the locomotive body. The surface is either rust or old paint that has turned to hard chips. All the sheet metal will have to be sanded back to a bare surface.

- All of the windows have been removed. New ones would have to be purchased, along with new gasket material, and installed.

- There is very little metal work to do to the body. There is some damage to a few of the access steps, but it is minor.

- A few of the handrails have some minor bends that need to be straightened out.

- The front and rear step boards are missing.

11.The horn and bell are in place and working.

- All lights in the locomotive work.

- The wheel sets appear to have no flat spots, and none appear to be too worn to provide any issues.

- There is no funding available for this project currently.

Restoration Project Selection Decision

As a group, the volunteers in Diesel Service have decided that, given a choice, they would prefer to restore SF560 rather than attempt a restoration of either one or both of the RSD12’s.

SF560 Weekly Report

This past week, volunteers worked on the locomotive for four days. The focus of the work was to determine why the engine would not inject fuel into the combustion chambers of the six cylinders.

At first, we thought that we understood the racks in the injection pumps and how the governor should move them but eventually realized that every one of the injection pumps was frozen solid and would not open up.

In the process, it was realized that sitting unused for 25 years resulted in the barrels and plungers in the fuel pumps freezing from either gum in very tight tolerance areas, or scuffing of surfaces. Either of those problems could keep the injection pump rack from moving.

This is what a rebuilt injection pump looks like.

One of our pumps was removed and this is what it looks like.

Notice the two washer looking devices on the rod on the left of the pump. That is where the governor actuated control rod connects to adjust the rack, which controls the flow of fuel to the injectors. The rack in the pump below is frozen solid after sitting unused for so many years.

This next picture shows the injection nozzle. It is a “Pintle” style injector. Most injection nozzles that we work with have a number of very small holes in the tip where fuel is squirted out in a fine mist into the combustion chamber. This type of injector has a small round cone pin in the end that opens up and a cone shape spray of fuel is injected into the combustion chamber.

Another nickname for it is an “ice cream cone”.

We don’t know if ours have a problem or not. They will also have to be tested along with rebuilding the injection pump.

However, before the pump and injector could be removed, the actuation cam was supposed to be set so that there was the least amount of pressure pushing on the injection pump. To do that, it was necessary to see the cam. To see that, the locomotive hood in that area had to be removed. Carl used the deck crane to lift it off.

After the hood was removed, a person could see the complete top of the Diesel engine and the cooling fan. The forward round top covers are the covers that are over the top crankshaft in this dual opposed piston engine. And they all leak oil because of failed gaskets.

After the hood was removed, a person could see the complete top of the Diesel engine and the cooling fan. The forward round top covers are the covers that are over the top crankshaft in this dual opposed piston engine. And they all leak oil because of failed gaskets.

Our next step is to locate qualified rebuild shops that can overhaul our fuel pumps or possibly supply used ones that are still functional. We must research all those options.

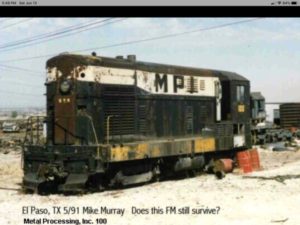

During our on-line research, we came across another picture of SF560 when it was in Texas. It appears to not have been used for some time judging by the location and trash stacked around it.

We are now at the point where funding will be required to continue.

Dave Althaus